+86-371-67991755

Automatic gravimetric feeding system has several features meet the requirements of modern large-scale production:

1) The principle of weight sensing part of the advanced, high precision. The general use of digital sensors, accuracy can reach one millionth.

2) high linearity of the material conveying part, the driving part can achieve high resolution.

3) Automatic gravimetric feeding system is a high degree of automation equipment. Such systems for automated production, usually with PLC control, chain systems and other control systems to meet the requirements of automated production.

4) system feeding accuracy. Due to the use of advanced feeders and advanced control systems, the entire system can achieve high accuracy. Generally can reach 0.5-1% accuracy. In special fields such as laboratories, application of experimental feeders can achieve 0.1-0.5% accuracy. Stability up to 2 SEGMA.

5) Automatic gravimetric feeding system is easy to operate. Generally, such systems have advanced monitoring systems and controllers and are more complicated in the commissioning phase. However, when all the parameters are set properly after the commissioning is completed, the operators only do simple operations such as calling parameters and setting output.

6) maintainability is strong. Due to the use of advanced control system, it is easy to achieve system fault diagnosis, which can shorten the troubleshooting time.

7)Automatic gravimetric feeding system is Powerful. Using advanced monitoring system, you can achieve complex recipe management, order management, history management, system control optimization, automatic parking management, chain management, remote diagnosis, detection and control.

8) The investment structure is reasonable. One-time investment is high. Due to the improvement of automation, the labor cost of operation can be saved, and the human-caused instability of product quality and avoid duplication of investment can be avoided.

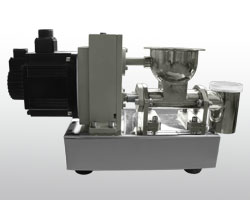

Batte is a loss in weight feeder manufacturer, supplying loss in weight feeder, volumetric feeders, and metering feeders.